I believe that many friends who do laser cutting processing will encounter similar problems.

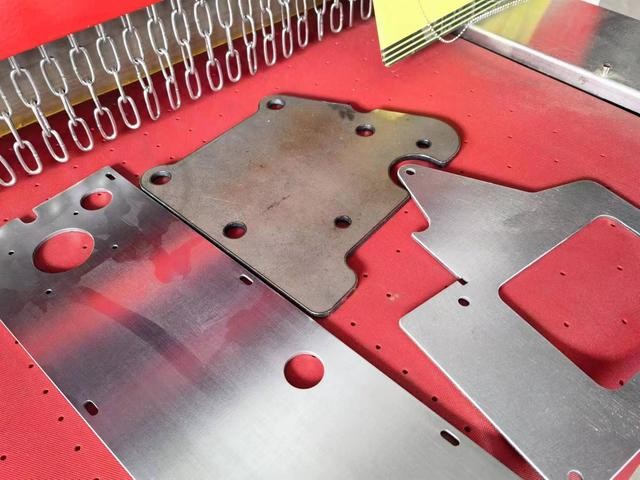

Laser cut sheet metal parts, the edge is very sharp, workers will cut their hands after hand contact!

Deburring machine is now the first choice of many laser cutting manufacturers.

So how many functions does the deburring machine have?

First, deburring

Shengxingli deburring machine to remove large burrs

Second, round the corners

Generating force deburring machining process

# Deburring machine #

Shengxingli Machinery Manufacturing is a research and development, manufacturing, sales, after-sales service in one of the professional customized special machine tool company. Our customers range from sheet metal industry scale users, well-known auto parts manufacturers and numerous smes. As a responsible enterprise that "respects technology and dares to innovate", we maintain good cooperation and exchanges with customers. We are mainly engaged in metal surface grinding equipment, metal fasteners, mold processing, manipulator, conveying equipment, cleaning and drying equipment and other professional tailor-made.

Through years of persistence and efforts in metal surface grinding technology and automation equipment, Shengxingli has achieved many achievements in sanding, grinding, deburring, wire drawing, automatic loading and unloading. Including intelligent automatic grinding machine: RR for stainless steel, carbon steel, aluminum and other metal materials, PCB and other non-metallic materials surface polishing, wire drawing, hair drawing and other processing; RP series for stamping, cutting, laser cutting, plasma cutting, flame cutting process produced by the burr and splash stains can be removed at one time, so that it presents a safe, reliable, round, beautiful perfect quality; The WX series deburrs the edges and holes of special-shaped parts and cast parts, so that the edges and holes of the workpiece can achieve R-arc effect.